Cellulose ether HPMC in cement mortar and gypsum based slurry, mainly play the role of water retention and thickening, can effectively improve the adhesion and sag resistance of slurry.

Air temperature, temperature and wind pressure rate can affect the evaporation rate of water in cement mortar and gypsum based products. In different seasons, the water retention effect of slurry can be adjusted by increasing or decreasing the amount of HPMC. In the construction of high temperature summer, in order to achieve the effect of water conservation, it is necessary to add HPMC products in sufficient quantity according to the formula. Otherwise, there will be insufficient hydration, strength reduction, cracking, hollow drum and shedding caused by too fast drying, and other quality problems. As the temperature decreases, the amount of HPMC can be gradually reduced, and the same water retention effect can be achieved.

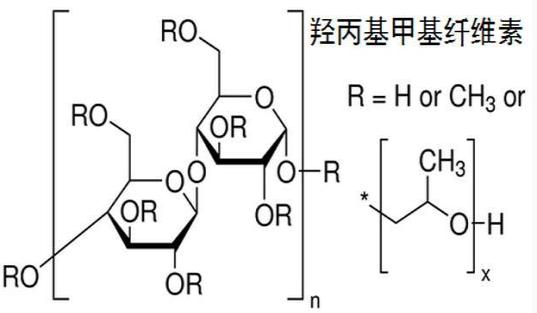

There are some differences and reasons for the water retention effect of the same amount of products added HPMC. Excellent HPMC series products can effectively solve the problem of water retention under high temperature. In the high temperature season, especially in hot and dry areas and thin layer construction on the sunny side, high quality HPMC is needed to improve the water retention of slurry. High quality HPMC, its methoxy and hydroxypropyl groups along the cellulose molecular chain uniform distribution, can improve hydroxyl and ether bond on the oxygen atoms and water association hydrogen bond ability, make free water into combined water. And effectively dispersed in the slurry and wrapped all solid particles, hydration reaction with inorganic cementing materials, and the formation of a layer of wetting film, water in the base gradually released for a long time, so as to effectively control the evaporation of water caused by high temperature weather, to achieve high water retention.

The water retention of HPMC products is often affected by the following factors:

1. The HPMC uniformity:Uniform reaction of HPMC, methoxy, hydroxypropoxy uniform distribution, high water retention.

2 HPMC thermal gel temperature:Hot gel has high

temperature and high water retention rate; otherwise, it has low water retention rate.

3. The viscosity of HPMC:When the viscosity of HPMC increases, the water retention rate also increases. When the

viscosity reaches a certain degree, the increase of water retention rate tends to be gentle.

4. HPMC content:The more HPMC is added, the higher the water retention rate and the better the water retention effect. In the range of 0.25-0.6%, the water conservation rate increased rapidly with the increase of the added amount. When the added amount increased further, the trend of increase of the water conservation rate became slow.

Post time: Jul-29-2022