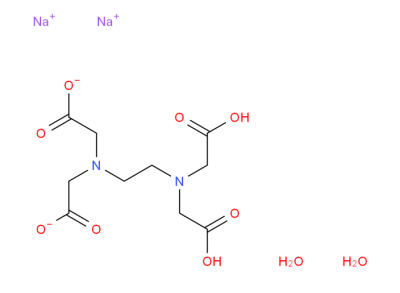

Ethylene Diamine Tetraacetic Acid Disodium (EDTA Na2)

Specifications :

|

Item |

Standard |

|

Appearance |

White Powder |

|

Assay(C10H14N2O8Na2.2H2O) |

≥99.0% |

|

Plumbum(Pb) |

≤0.0005% |

|

Ferrum(Fe) |

≤0.001% |

|

Chloride(Cl) |

≤0.05% |

|

Sulfate(SO4) |

≤0.05% |

|

PH(50g/L; 25℃) |

4.0-6.0 |

|

Particle Size |

<40mesh≥98.0% |

Application:

EDTA 2NA is an important complexing agent for complexing metal ions and separating metals. This product is used as bleaching fixing solution for color photographic material developing and processing, and dyeing auxiliary, fiber treatment agent, cosmetic additive, medicine, food, agricultural chemical microfertilizer production, blood anticoagulant, complexing agent, detergent, stabilizer, synthetic rubber, polymerization initiator and heavy metal quantitative analysis agent, etc. In the chlorinated reduction initiation system for SBR polymerization, disodium EDTA is used as a component of the active agent, mainly for complexing iron ions and controlling the rate of polymerization reaction.

Production Process:

1.Slowly add the mixture of sodium cyanide and formaldehyde to the aqueous solution of ethylenediamine in a certain ratio, and pass air at 85℃ under reduced pressure to remove the ammonia gas. After the reaction, adjust the Ph value to 4.5 with concentrated sulfuric acid, and then decolorize, filter, concentrate, crystallize and separate, and dry to get the finished product.

2.Mix 100kg of chloroacetic acid, 100kg of ice and 135kg of 30% NaOH solution, add 18kg of 83%~84% ethylenediamine under stirring, and keep it at 15℃ for 1h. Slowly add 30% NaOH solution in batches until the reactant becomes alkaline, and keep it at room temperature for 12h. Heat to 90℃, add activated carbon to decolorize. The filtrate is adjusted to 4.5 Ph with hydrochloric acid and concentrated and filtered at 90℃; the filtrate is cooled, crystallized, separated and washed, and dried at 70℃ to obtain the finished product.

3.Made by the action of ethylenediaminetetraacetic acid and sodium hydroxide solution: In a 2L reaction flask equipped with a stirrer, add 292g ethylenediaminetetraacetic acid and 1.2L water. Add 200mL of 30% sodium hydroxide solution under stirring and heat until all the reaction is finished. Add 20% hydrochloric acid and neutralize to pH=4.5, heat to 90℃ and concentrate, filter. The filtrate is cooled and crystals are precipitated. Extract and separate, wash with distilled water, dry at 70℃, and get the product EDTA 2NA.

4.Add ethylenediaminetetraacetic acid and water to the enameled reaction tank, add sodium hydroxide solution under stirring, heat until all the reaction, add hydrochloric acid to pH 4.5, heat to 90°C and concentrate, filter, the filtrate is cooled, filter out the crystals, wash with water, dry at 70°C, and get EDTA 2NA.