-

Activated Carbon For Pharmaceuticals Industry

Pharmaceutical industry activated carbon technology

Wood base pharmaceutical industry activated carbon are made from high quality sawdust which is refined by scientific method and with the appearance of black powder.Pharmaceutical industry activated carbon characteristics

It is featured by large specific surface, low ash,great pore structure, strong adsorption capacity, fast filtration speed and high purity of decolorization etc. -

Honeycomb Activated Carbon

Technology

The series of activated carbon with special coal based powder activated carbon、coconut shell or special wood based activated carbon as raw materials, after the scientific formula refined processing of the high activity microcrystalline structure carrier special activated carbon.

Characteristics

This series of activated carbon with large surface area, developed pore structure, high adsorption, high strength easy regeneration function.

-

Solvent Recovery

Technology

The series of activated carbon based on coal or coconut shell with physical method.

Characteristics

The series of activated carbon with large surface area, developed pore structure, high adsorption speed and capacity, high hardness.

-

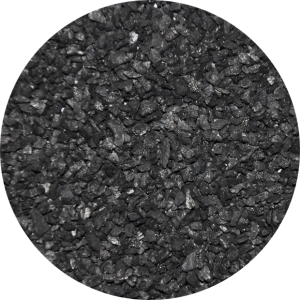

Gold Recovery

Technology

Fruit shell based or coconut shell based granular activated carbon with physical method.

Characteristics

The series of activated carbon has high speed of gold loading and elution, optimum resistance to mechanical attrition.

-

Desulfurization &Denitration

Technology

The series of activated carbon is made from strictly selected top quality coal and blended coal. Mixing of coal powder with tar and water, extrusion of the mixed material into Columnar under oil pressure, followed by carbonization, activation and oxidation.

-

Impregnated & Catalyst Carrier

Technology

The series of activated carbon select high quality coal as raw materials by impregnating with different reagents.

Characteristics

The series of activated carbon with good adsorption and catalysis, provide all purpose gas phase protection.

-

Activated Carbon For Air & Gas Treatments

Technology

These series of activated carbon in granular form are made from fruit net shell or coal, activated via high temperature water steam method, under the process of crushing after treatment.Characteristics

These series of activated carbon with large surface area, developed pore structure, high adsorption, high strength, well washable, easy regeneration function.Using Fields

To be used for gas purification of chemical materials, chemical synthesis, the pharmaceutical industry, drink with carbon dioxide gas, hydrogen, nitrogen, chlorine, hydrogen chloride, acetylene, ethylene, inert gas. Used for atomic facilities such as exhaust purification, division and refined. -

Activated Carbon For Water treatment

Technology

These series of activated carbo are made from coal.

The activated carbon processes are accomplished by using one combination of the following steps:

1.) Carbonization: Material with carbon content is pyrolyzed at temperatures in the range of 600–900℃, in absence of oxygen (usually in inert atmosphere with gases like argon or nitrogen).

2.)Activation/ Oxidation: Raw material or carbonised material is exposed to oxidizing atmospheres (carbon monoxide, oxygen, or steam) at temperatures above 250℃, usually in the temperature range of 600–1200 ℃. -

Activated Carbon For Chemical Industry

Technology

These series of activated carbon in powder form are made from sawdust, charcoal or fruit nut shell with good quality and hardness, activated via chemical or high temperature water method, under the after treatment process of scientific formula refined form.Characteristics

These series of activated carbon with large surface area, developed microcellular and mesoporous structure, large volume adsorption, high rapid filtration etc. -

Activated Carbon For Food Industry

Technology

These series of activated carbon in powder and granular form are made from sawdust and fruit nut shell, activated via physical and chemical methods, under the process of crushing, after treatment.Characteristics

These series of activated carbon with developed mesoporous structure, high rapid filtering, large adsorption volume, short filtering time, good hydrophobic property etc.

We take integrity and win-win as operation principle, and treat every business with strict control and care.