Hydroxypropyl methyl cellulose is divided into several kinds, and what is the difference in its use?

HPMC can be divided into instant and hot-melt types. Instant products disperse rapidly in cold water and disappear into water. At this time, the liquid has no viscosity, because HPMC is only dispersed in water and does not really dissolve. After about 2 minutes (stirring), the viscosity of the liquid slowly increases, forming a transparent white viscous colloid. Hot soluble products can disperse rapidly in hot water and disappear in hot water when they are agglomerated in cold water. When the temperature drops to a certain temperature (according to the gel temperature of the product), the viscosity slowly appears until a transparent viscous colloid is formed.

How to judge the quality of hydroxypropyl methyl cellulose simply and intuitively?

Whiteness. Although whiteness cannot determine whether HPMC is easy to use, and if whitening agents are added in the production process, it will affect its quality, most good products have good whiteness.

Fineness: the fineness of HPMC is generally 80 mesh and 100 mesh, and 120 mesh is less. The finer the fineness, the better.

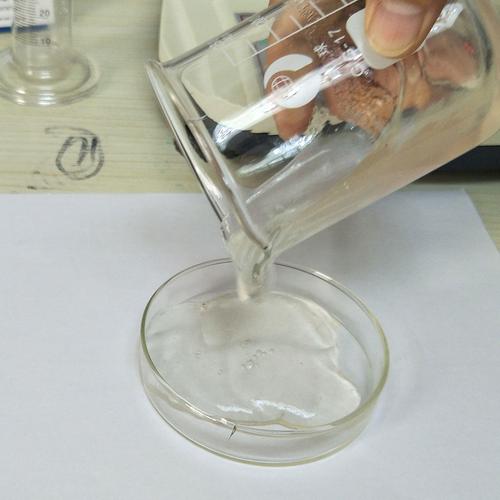

Light transmittance: after HPMC is put into water to form a transparent colloid, look at its light transmittance. The greater the light transmittance, the better. It means that there are less insoluble substances in it. The transmittance of the vertical reactor is generally good, and that of the horizontal reactor is worse. However, it does not mean that the quality of the vertical reactor is better than that of the horizontal reactor. There are many factors determining the product quality.

Specific gravity: the larger the specific gravity is, the heavier it is, the better it is. Generally, it is because the content of hydroxypropyl in it is high. If the content of hydroxypropyl is high, the water retention is better.

Specific gravity: the larger the specific gravity is, the heavier it is, the better it is. Generally, it is because the content of hydroxypropyl in it is high. If the content of hydroxypropyl is high, the water retention is better.

what are the dissolution methods of hydroxypropyl methyl cellulose?

All models can be added to materials by dry mixing method;

When it needs to be directly added to the aqueous solution at room temperature, it is better to use the cold water dispersion type. Generally, it can be thickened within 10-90 minutes after adding (stirring)

Ordinary models can be dissolved after mixing and dispersing with hot water, adding cold water, stirring and cooling;

If caking and wrapping occurs during dissolution, it is due to insufficient mixing or ordinary models are directly added to cold water. At this time, it should be quickly stirred.

If bubbles are generated during dissolution, they can be removed by standing for 2-12 hours (the specific time depends on the consistency of the solution), vacuuming, pressurizing and other methods, or adding an appropriate amount of defoamer.

What role does hydroxypropyl methyl cellulose play in the application of putty powder, and whether there is chemistry?

In the putty powder, it plays three roles: thickening, water retention and construction. Thickening, cellulose can thicken, play the role of suspension, keep the solution uniform up and down, and resist sagging. Water retention: make putty powder dry slowly, and assist lime calcium to react under the action of water. Construction: cellulose has lubricating effect, which can make putty powder have good workability. HPMC does not participate in any chemical reaction, but only plays an auxiliary role.

What is the gel temperature of hydroxypropyl methyl cellulose related to?

The gel temperature of HPMC is related to its methoxyl content. The lower the methoxyl content, the higher the gel temperature.

is there any relationship between the dropping of putty powder and hydroxypropyl methyl cellulose?

It matters!!! HPMC has poor water retention, which will cause powder loss.

The application of hydroxypropyl methyl cellulose in putty powder, what is the reason for the bubbles in putty powder?

HPMC plays three roles in the putty powder: thickening, water retention and construction. The reasons for bubbles are as follows:

Too much water is added.

If you scrape another layer on the bottom layer before it is dry, it is also easy to blister.

Post time: Sep-27-2022