Air and water pollution remain among the most pressing global issues, putting vital ecosystems, food chains, and the environment necessary for human life in jeopardy.

Water pollutions tend to stem from heavy metal ions, refractory organic pollutants, and bacteria—toxic, harmful pollutants from industrial and wastewater processes which do not decompose naturally. This issue is compounded by the eutrophication of bodies of water which can result in favorable conditions for large numbers of bacteria to reproduce, further polluting and adversely affecting water quality.

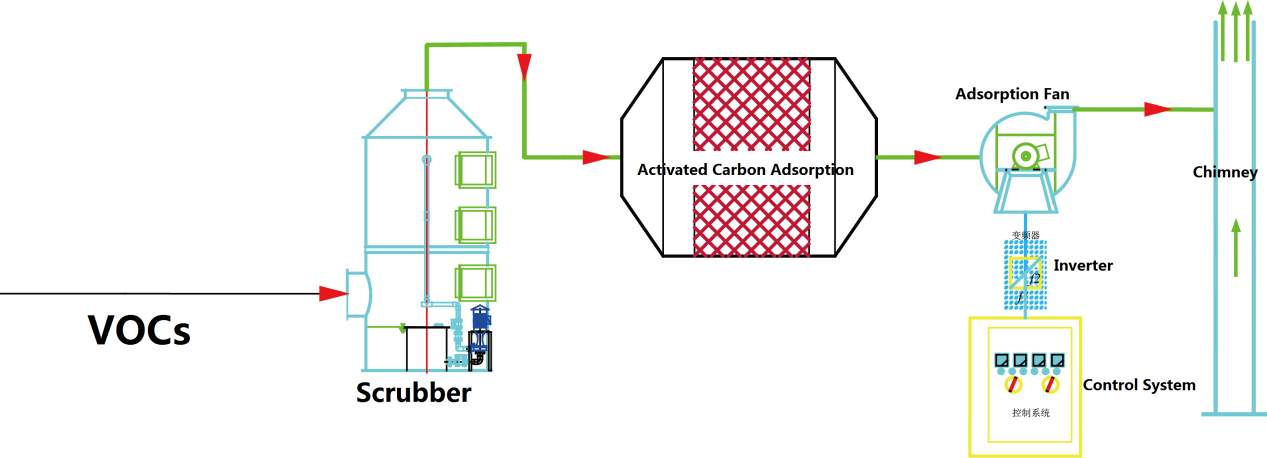

Air pollution is primarily comprised of volatile organic compounds (VOCs), nitrogen oxides (NOx), sulfur oxides (SOx), and carbon dioxide (CO2) – pollutants that primarily stem from the burning of fossil fuels. The impact of CO2 as a greenhouse gas has been widely documented, with significant amounts of CO2 substantially impacting the Earth’s climate.

A range of technologies and approaches has been developed in order to respond to these issues, including activated carbon adsorption, ultrafiltration, and advanced oxidation processes (AOPs) aiming to tackle water pollution issues.

From the VOCs adsorption system, you will find that Columnar activated carbon is an integral part and popular used on the VOCs treatment systems as cost-effective adsorbent media.

Activated carbon, in widespread industrial use since the end of World War I, was by the mid-1970s the preferred choice for air-pollution control of VOCs because of its selectivity in removing organic vapors from gas streams even in the presence of water.

The conventional carbon-bed adsorption system—one relying on team regeneration—can be an effective technique for recovering solvents for their economic value. Adsorption occurs when a solvent vapor comes into contact with a carbon bed and is collected on the porous activated carbon surface.

Carbon-bed adsorption is effective in solvent-recovery operations at solvent concentrations above 700 ppmv. Because of ventilation requirements and fire codes, the normal practice has been to keep the solvent concentrations below 25% of the lower explosive limit (LEL).

Post time: Jan-20-2022