What Does Activated Carbon Do?

Activated carbon attracts and holds organic chemicals from vapor and liquid streams cleaning them of unwanted chemicals. It does not have a great capacity for these chemicals, but is very cost effective for treating large volumes of air or water to remove dilute concentrations of contamination. For a better perspective, when individuals ingest chemicals or are experiencing food poisoning, they are instructed to drink a small amount of activated carbon to soak up and remove the poisons.

What Will Activated Carbon Remove?

Organic chemicals are attracted to carbon the best. Very few inorganic chemicals will be removed by carbon. The molecular weight, polarity, solubility in water, temperature of the fluid stream and concentration in the stream are all factors that affect the capacity of the carbon for the material to be removed. VOCs such as Benzene, Toluene, Xylene, oils and some chlorinated compounds are common target chemicals removed through use of carbon. Other large uses for activated carbon are the removal of odors and color contamination.

What Is Activated Carbon Made From?

Here at General Carbon, we carry activated carbon made from bituminous coal, lignite coal, coconut shell and wood.

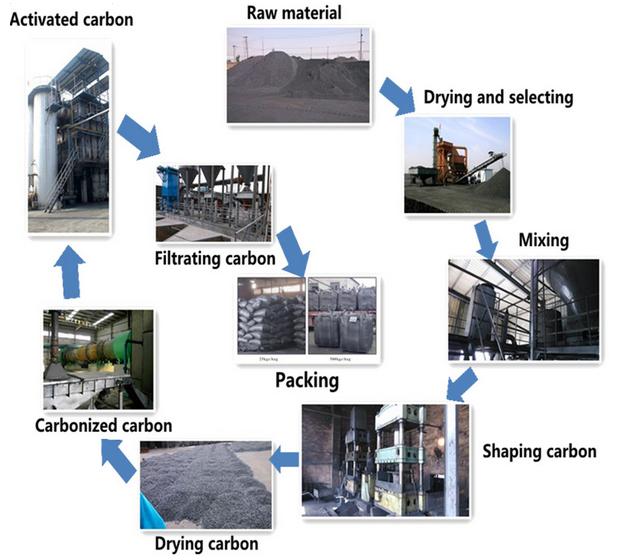

How Is Activated Carbon Made?

There are two different ways to make activated carbon but for this article we will provide you with the more efficient way that will create higher quality and purer activated carbon. Activated carbon is made by being placed in a tank without oxygen and subjecting it to extremely high temperatures, 600-900 degrees Celsius. Afterwards, the carbon is exposed to different chemicals, commonly argon and nitrogen, and again placed in a tank and superheated from 600-1200 degrees Celsius. The second time the carbon is placed in the heat tank, it is exposed to steam and oxygen. Through this process, a pore structure is created and the usable surface area of the carbon greatly increases.

Which Activated Carbon Should I Use?

The first decision for using carbon is to treat a liquid or vapor stream. Air is best treated using large particles of carbon to reduce the pressure drop through the bed. Smaller particles are used with liquid applications to reduce the distance the chemicals have to travel to be adsorbed inside the carbon. Whether your project treats vapor or liquid, there are different sized carbon particles available. There are all different substrates such as coal or coconut shell base carbon to consider. Talk to a General Carbon representative to get the best product for your job.

How Do I Use Activated Carbon?

Carbon is typically used in a column contactor. The columns are called adsorbers and are designed specifically for air and water. The design is engineered for loading (amount of fluid per area cross section), contact time (a minimum contact time is needed to insure required removal) and pressure drop through the adsorber (needed to size container pressure rating and fan/pump design rating). The standard General Carbon adsorbers are pre-engineered to meet all of the requirements for good adsorber design. We can also design special designs for applications outside the normal range.

How Long Does Activated Carbon Last?

Carbons capacity for chemicals depends on many things. The molecular weight of the chemical being removed, the concentration of the chemical in the stream being treated, other chemicals in the treated stream, operating temperature of the system and polarity of the chemicals being removed all affect the life of a carbon bed. Your General Carbon representative will be able to provide you with an expected operating life based on the amounts and chemicals in your stream.

Post time: Sep-27-2022