Factory making Tile Cement Adhesive Hpmc - Hydroxypropyl Methyl Cellulose (HPMC) Used for Tile adhesives – MEVA

Factory making Tile Cement Adhesive Hpmc - Hydroxypropyl Methyl Cellulose (HPMC) Used for Tile adhesives – MEVA Detail:

Better Workability

The shear-thinning and air-entraining properties of HPMC give modified tile adhesives a better workability, as well as higher work efficiency, from yield/coverage and faster tiling sequence stand points.

Improves Water Retention

We can improve water retention in tile adhesives. This helps increase final adhesion strength as well as prolong open time. Prolonged open time also leads to faster tiling rate as it allows the worker to trowel a larger area before setting the tiles down, as opposed to troweling the adhesive onto each tile before setting the tile down.

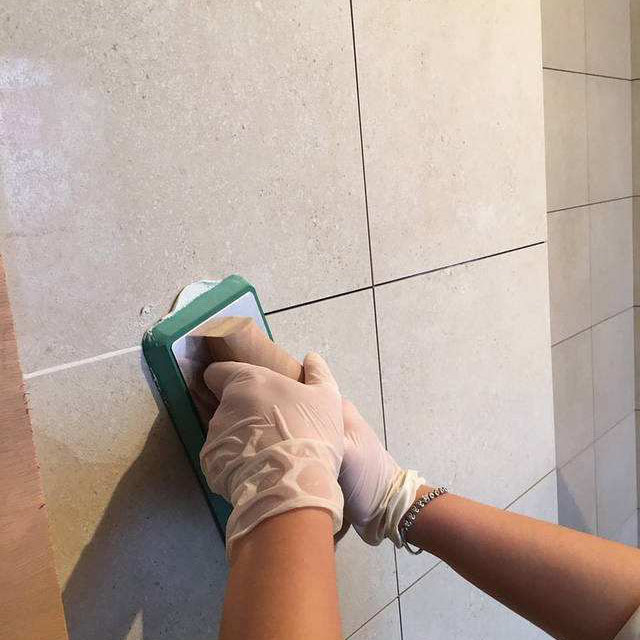

Provides Slip/Sag Resistance

Modified HPMC also provides slip/sag resistance, so that heavier or non-porous tiles do not slip down the vertical surface.

Increases Adhesion Strengths

As mentioned before, it allows the hydration reaction to complete farther, thus allowing higher final adhesion strength to develop

Note:Products can be customized according to customer needs.

Product detail pictures:

Related Product Guide:

We hold strengthening and perfecting our items and repair. At the same time, we get the job done actively to do research and progress for Factory making Tile Cement Adhesive Hpmc - Hydroxypropyl Methyl Cellulose (HPMC) Used for Tile adhesives – MEVA , The product will supply to all over the world, such as: Armenia, Somalia, Slovak Republic, For anyone who is keen on any of our goods right after you view our product list, please really feel absolutely free to get in touch with us for inquiries. You are able to send us emails and contact us for consultation and we shall respond to you as soon as we can. If it's easy, you may locate out our address in our web-site and come to our business for far more information of our products by your self. We are always ready to construct extended and steady co-operation relations with any possible customers in the related fields.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!