factory low price Dry Mix Mortar - Hydroxypropyl Methyl Cellulose (HPMC) Used for Tile adhesives – MEVA

factory low price Dry Mix Mortar - Hydroxypropyl Methyl Cellulose (HPMC) Used for Tile adhesives – MEVA Detail:

Better Workability

The shear-thinning and air-entraining properties of HPMC give modified tile adhesives a better workability, as well as higher work efficiency, from yield/coverage and faster tiling sequence stand points.

Improves Water Retention

We can improve water retention in tile adhesives. This helps increase final adhesion strength as well as prolong open time. Prolonged open time also leads to faster tiling rate as it allows the worker to trowel a larger area before setting the tiles down, as opposed to troweling the adhesive onto each tile before setting the tile down.

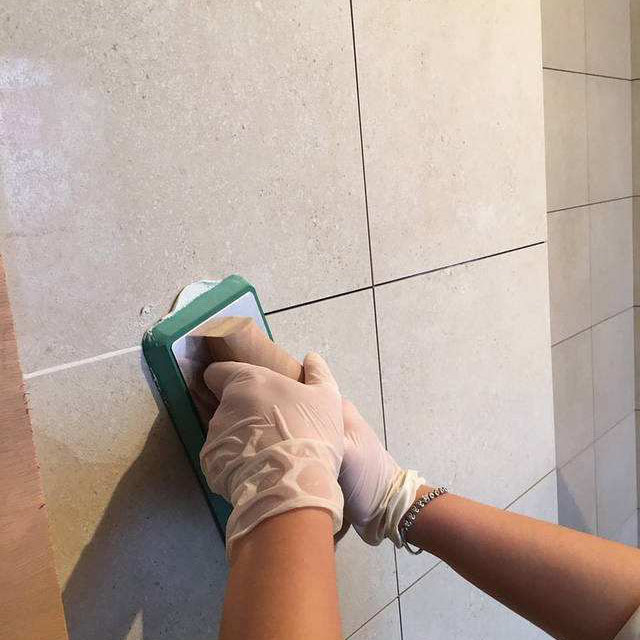

Provides Slip/Sag Resistance

Modified HPMC also provides slip/sag resistance, so that heavier or non-porous tiles do not slip down the vertical surface.

Increases Adhesion Strengths

As mentioned before, it allows the hydration reaction to complete farther, thus allowing higher final adhesion strength to develop

Note:Products can be customized according to customer needs.

Product detail pictures:

Related Product Guide:

Our growth depends on the superior equipment ,exceptional talents and continuously strengthened technology forces for factory low price Dry Mix Mortar - Hydroxypropyl Methyl Cellulose (HPMC) Used for Tile adhesives – MEVA , The product will supply to all over the world, such as: Bulgaria, Kyrgyzstan, Angola, Our team knows well the market demands in different countries, and is capable of supplying suitable quality products and solutions at the best prices to different markets. Our company has already set up a experienced, creative and responsible team to develop clients with the multi-win principle.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.