Factory directly supply Hpmc For Plaster - Hydroxypropyl Methyl Cellulose (HPMC) Used for Tile adhesives – MEVA

Factory directly supply Hpmc For Plaster - Hydroxypropyl Methyl Cellulose (HPMC) Used for Tile adhesives – MEVA Detail:

Better Workability

The shear-thinning and air-entraining properties of HPMC give modified tile adhesives a better workability, as well as higher work efficiency, from yield/coverage and faster tiling sequence stand points.

Improves Water Retention

We can improve water retention in tile adhesives. This helps increase final adhesion strength as well as prolong open time. Prolonged open time also leads to faster tiling rate as it allows the worker to trowel a larger area before setting the tiles down, as opposed to troweling the adhesive onto each tile before setting the tile down.

Provides Slip/Sag Resistance

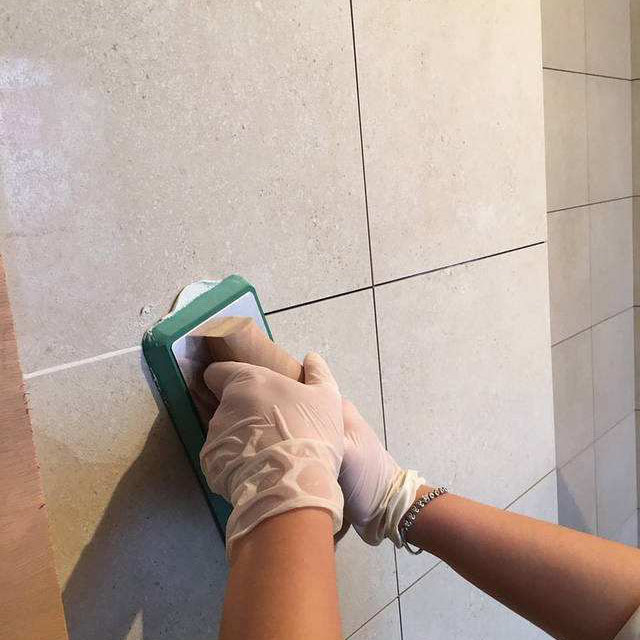

Modified HPMC also provides slip/sag resistance, so that heavier or non-porous tiles do not slip down the vertical surface.

Increases Adhesion Strengths

As mentioned before, it allows the hydration reaction to complete farther, thus allowing higher final adhesion strength to develop

Note:Products can be customized according to customer needs.

Product detail pictures:

Related Product Guide:

Adhering to your principle of "quality, assistance, performance and growth", we have now gained trusts and praises from domestic and international customer for Factory directly supply Hpmc For Plaster - Hydroxypropyl Methyl Cellulose (HPMC) Used for Tile adhesives – MEVA , The product will supply to all over the world, such as: Costa Rica, Canada, Austria, We've established long-term, stable and good business relationships with many manufacturers and wholesalers around the world. Currently, we've been looking forward to even greater cooperation with overseas customers based on mutual benefits. You should feel free to contact us for more details.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.