OEM manufacturer Emulsion Putty - Hydroxypropyl Methyl Cellulose (HPMC) Used for Tile adhesives – MEVA

OEM manufacturer Emulsion Putty - Hydroxypropyl Methyl Cellulose (HPMC) Used for Tile adhesives – MEVA Detail:

Better Workability

The shear-thinning and air-entraining properties of HPMC give modified tile adhesives a better workability, as well as higher work efficiency, from yield/coverage and faster tiling sequence stand points.

Improves Water Retention

We can improve water retention in tile adhesives. This helps increase final adhesion strength as well as prolong open time. Prolonged open time also leads to faster tiling rate as it allows the worker to trowel a larger area before setting the tiles down, as opposed to troweling the adhesive onto each tile before setting the tile down.

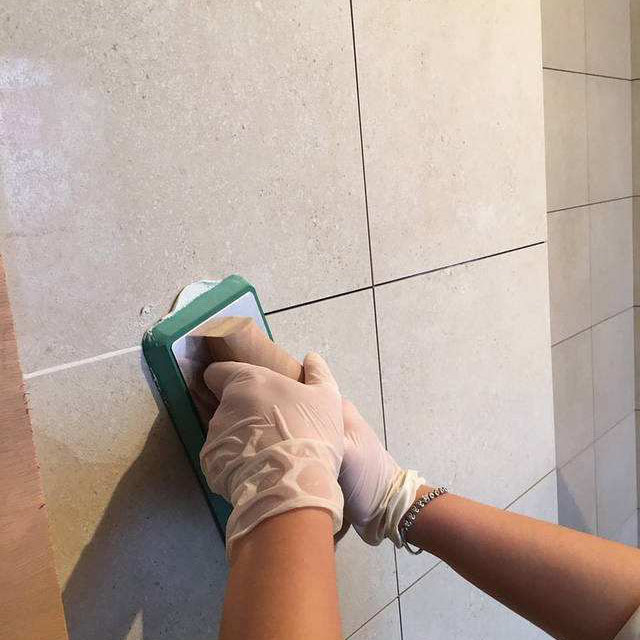

Provides Slip/Sag Resistance

Modified HPMC also provides slip/sag resistance, so that heavier or non-porous tiles do not slip down the vertical surface.

Increases Adhesion Strengths

As mentioned before, it allows the hydration reaction to complete farther, thus allowing higher final adhesion strength to develop

Note:Products can be customized according to customer needs.

Product detail pictures:

Related Product Guide:

Bear "Customer initially, High quality first" in mind, we do the job closely with our customers and supply them with efficient and skilled providers for OEM manufacturer Emulsion Putty - Hydroxypropyl Methyl Cellulose (HPMC) Used for Tile adhesives – MEVA , The product will supply to all over the world, such as: Melbourne, Denver, Canada, At present our sales network is growing continually, improving service quality to meet customer's demand. If you are interested in any products , please contact us at anytime. We are looking forward to forming successful business relationships with you in near future.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.